Responsive materials promise machines and structures that adapt their shape and properties to changing environments helping to advance everything from avionics to chip production. However turning that promise into reproducible engineering, requires more than clever chemistries: it needs design methods that connect stimuli, materials, structures, and manufacturing into a single pipeline.

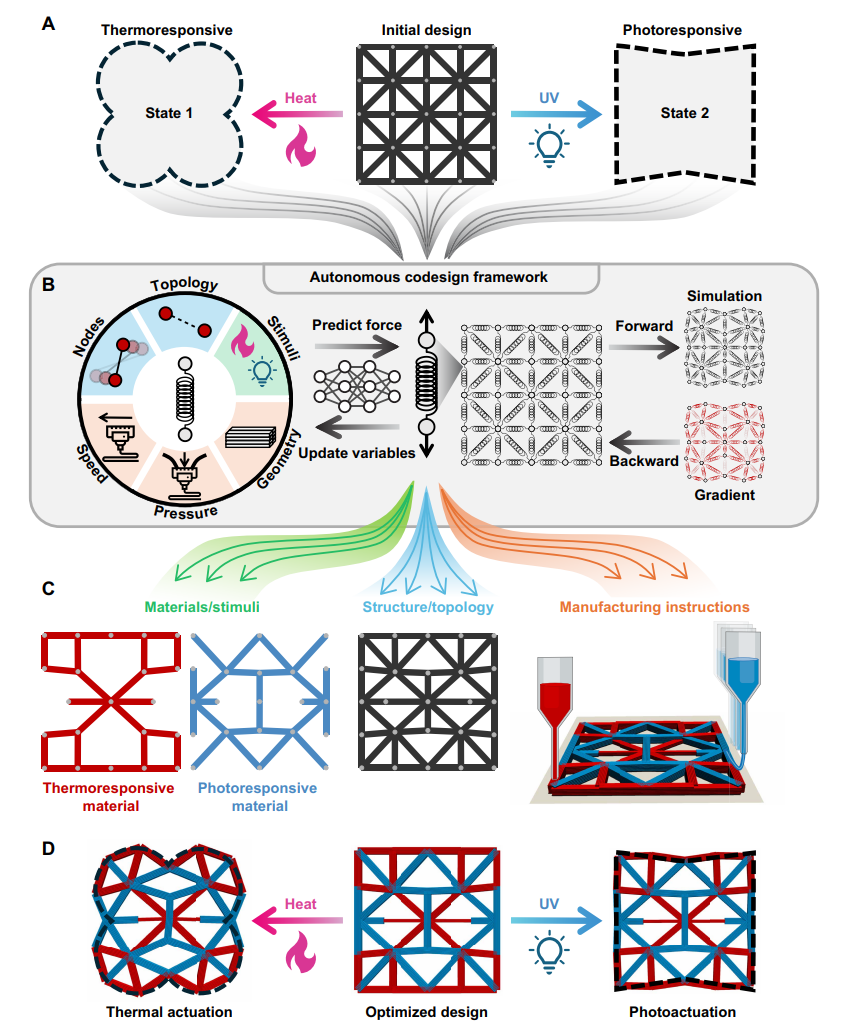

A new study presents exactly that - a unified, autonomous codesign framework that jointly optimizes structure, materials, stimuli, and fabrication instructions to realize target shape morphing in liquid crystal elastomer (LCE) networks (Wang et al., 2025).

The work, published in Science Advances by researchers from Carnegie Mellon University and Northwestern University, integrates a generalized topology optimization (TO) scheme with a hybrid data-physics differentiable simulation and a multimaterial, high-temperature direct ink writing (HOT-DIW) printing platform.

The result is print-ready designs that morph into prescribed shapes under multiple stimuli - heat and ultraviolet (UV) light - without relying on human heuristics.

Key Takeaways

- Unified, autonomous codesign: simultaneously optimizes network topology, geometry, material assignment, print speeds/pressures, and number of passes to achieve target morphing.

- Hybrid data-physics simulation: neural networks fit to measured stress–strain curves drive a differentiable spring-network simulator; gradients feed a generalized TO (topology optimization) solver.

- Manufacturing-aware by design: the optimizer outputs edge-level print instructions; ignoring them degrades performance markedly in ablation experiments.

- Multistimuli behavior: printed LCE networks morph under heat (thermotropic) and UV light (photomechanical), including different shapes for different stimuli in the same part.

- Fast iteration: GPU-accelerated differentiable simulation enables minutes-scale optimization with hundreds of mixed-variable design parameters.

- Applications: soft robotics, programmable materials, mechanical computing, and biomedical morphing systems, among others.

Overview

The central thesis is to bring topology optimization, differentiable simulation, and fabrication together so that the “what” and the “how” are solved jointly. The team models network-like materials as generalized nonlinear springs with prestrain.

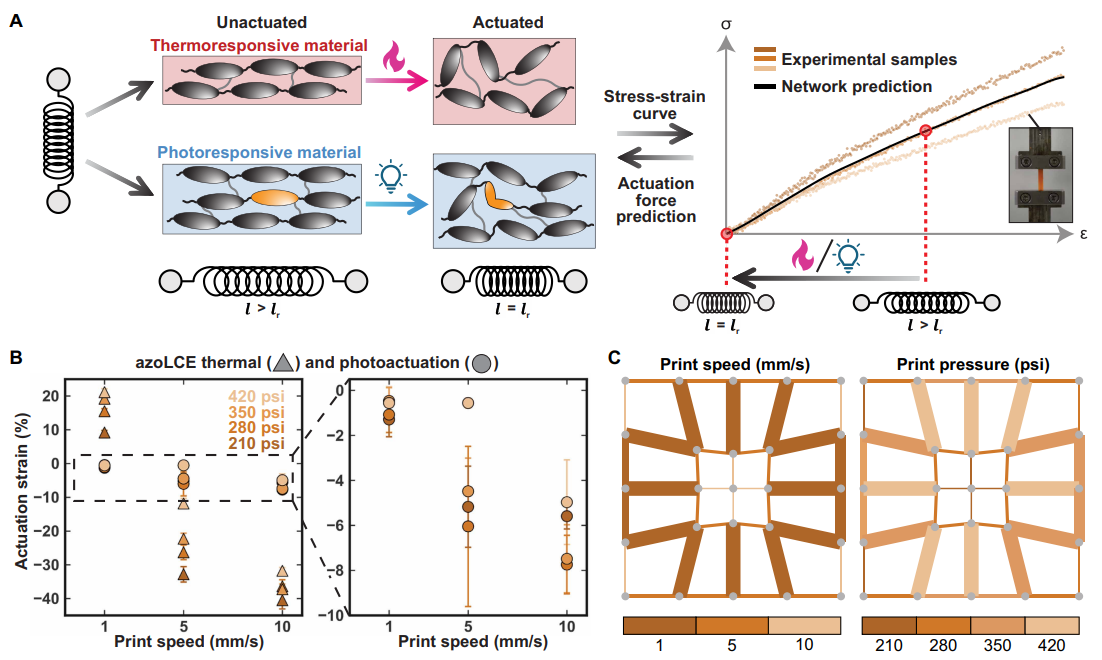

Each edge’s response depends on material choice (azoLCE vs neatLCE), stimulus (thermal vs photo), and fabrication parameters (print speed, pressure, and the number of printing paths/passes).

To capture these complex, process-dependent behaviors, the authors train neural networks on experimentally measured stress–strain data for printed LCEs. Those networks become constitutive surrogates that predict spring forces as the elements deform.

The forward simulation is implemented in Taichi for GPU-accelerated, differentiable physics, using symplectic Euler integration to relax the structure to equilibrium under actuation.

Automatic differentiation provides gradients of nodal positions with respect to all design variables, enabling a generalized TO solver to update geometry, topology, materials, and process parameters together.

This is materially different from conventional TO, which usually stops at material layout and often ignores manufacturing. Here, manufacturing is a first-class variable.

Why networks and not solid continua? Networks relax geometric constraints, enabling large apparent shape changes without extreme local strains and making it practical to vary process parameters edge-by-edge. Prior work shows mechanical networks have rich, programmable behavior spaces (Rocks et al., 2017), and the team leverages that combinatorial freedom effectively.

Why It Matters

Shape-morphing materials are moving from demonstrations to real devices. To scale, engineers need tools that navigate the tangled design space spanning materials, stimuli, geometry, and fabrication constraints. The presented framework does this autonomously, turning high-level morphing goals into print-ready instructions. That shift matters for several reasons:

First, it bridges the chasm between simulation and manufacturing. By fitting neural surrogates to measured data and optimizing over process parameters, the method accounts for the realities of printing - feature size, anisotropy from shear alignment, and the tunable actuation that print speed and pressure impart to LCEs (Wang et al., 2025; Kotikian et al., 2018).

Second, it supports multistimuli designs where different stimuli drive distinct behaviors in the same architecture - an essential capability for multifunctional soft robots and adaptive systems. Third, it runs fast enough to be practical, thanks to differentiable programming and GPUs (Hu et al., 2019).

Discussion

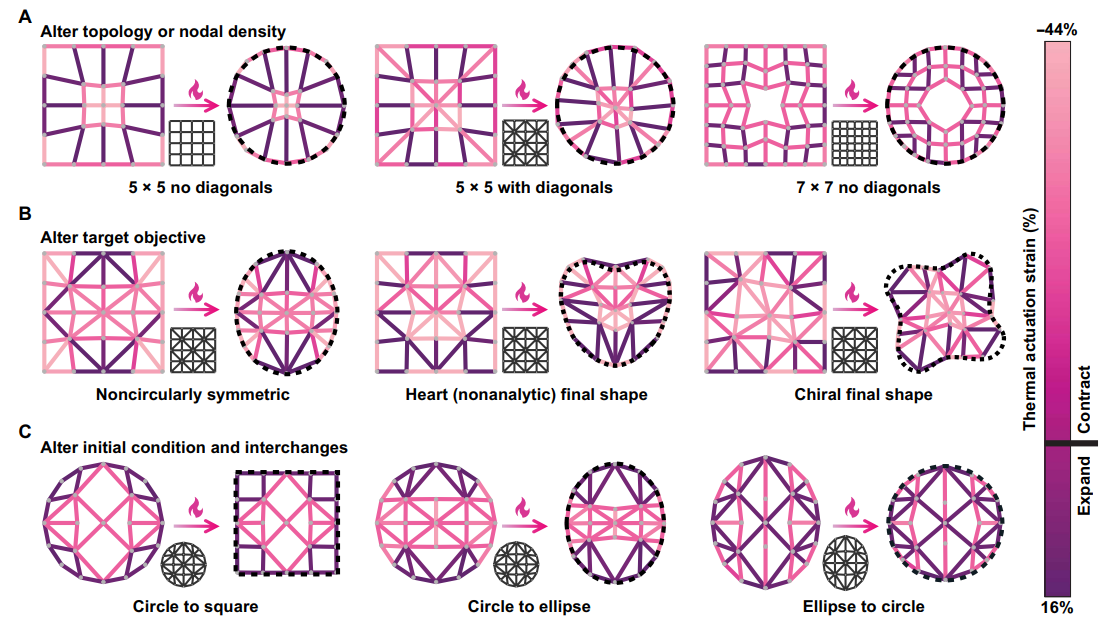

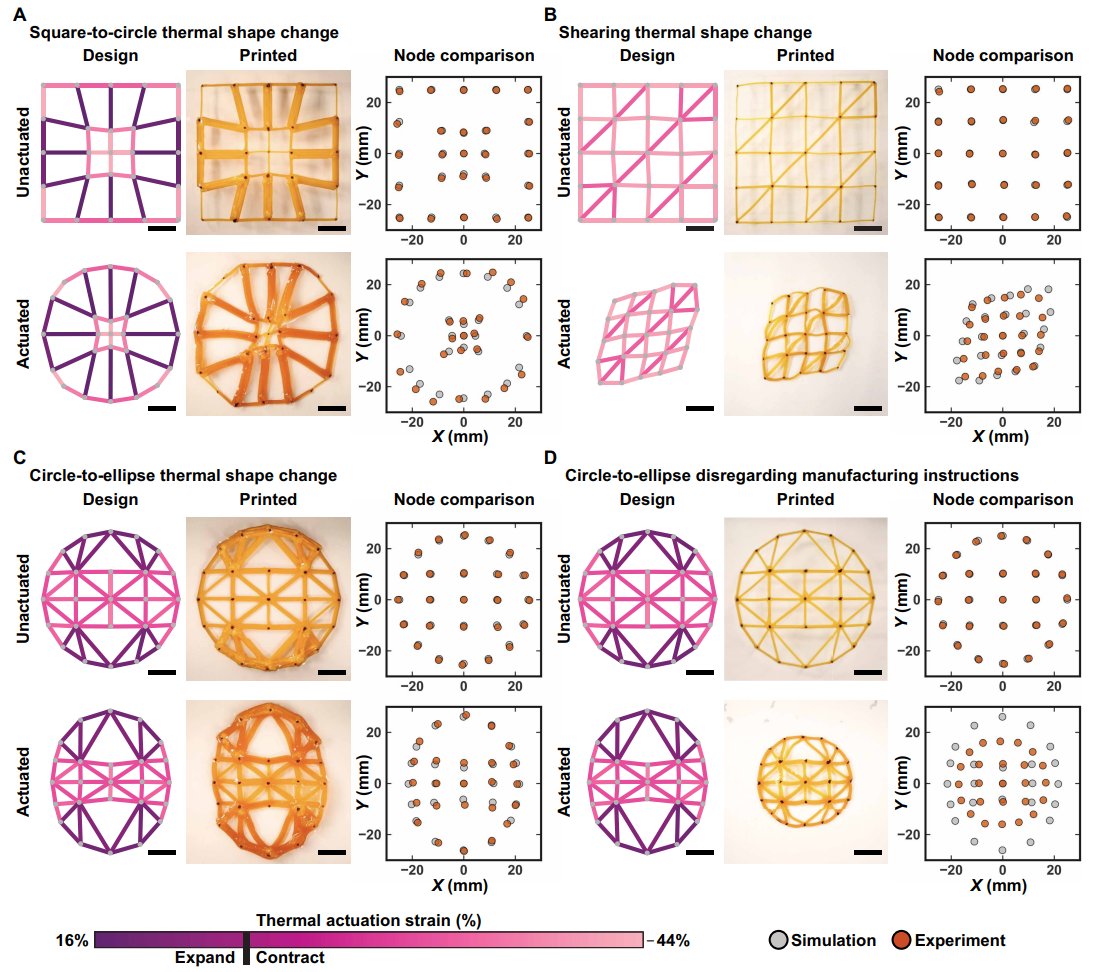

The paper’s experiments proceed in three stages: thermoresponsive morphing, photoresponsive morphing, and multistimuli morphing. In each, the optimizer outputs both structure and a per-edge bill of process parameters (speed, pressure, number of passes). The team then prints the networks via multimaterial HOT-DIW and validates morphing against simulation by tracking node positions and key geometric metrics.

Thermal morphing.

A series of designs transform between classical shapes, such as square-to-circle, as well as more irregular targets (e.g., a heart and chiral forms). Across these, a consistent pattern emerges: the optimizer separates edges into two functional groups. One forms a stiff skeleton (lower induced strain, larger cross-sections, higher pressure, lower speed), while the other serves as actuators (higher induced strain, smaller cross-sections, lower pressure, higher speed). The division resembles muscle–skeleton interplay and proves robust across starting topologies. Quantitatively, square-to-circle prints achieve node-wise agreement with R² > 0.99 and < 2% error in global shape parameters, such as circle diameter.

A control experiment underscores the importance of manufacturing-aware design. Printing a circle-to-ellipse design without the optimized process parameters produced an isotropic shrinkage into a smaller circle. Node-level error and global shape mismatch both worsened substantially relative to the fully codesigned print. In other words, the “how” of printing is not incidental—it is part of the design space.

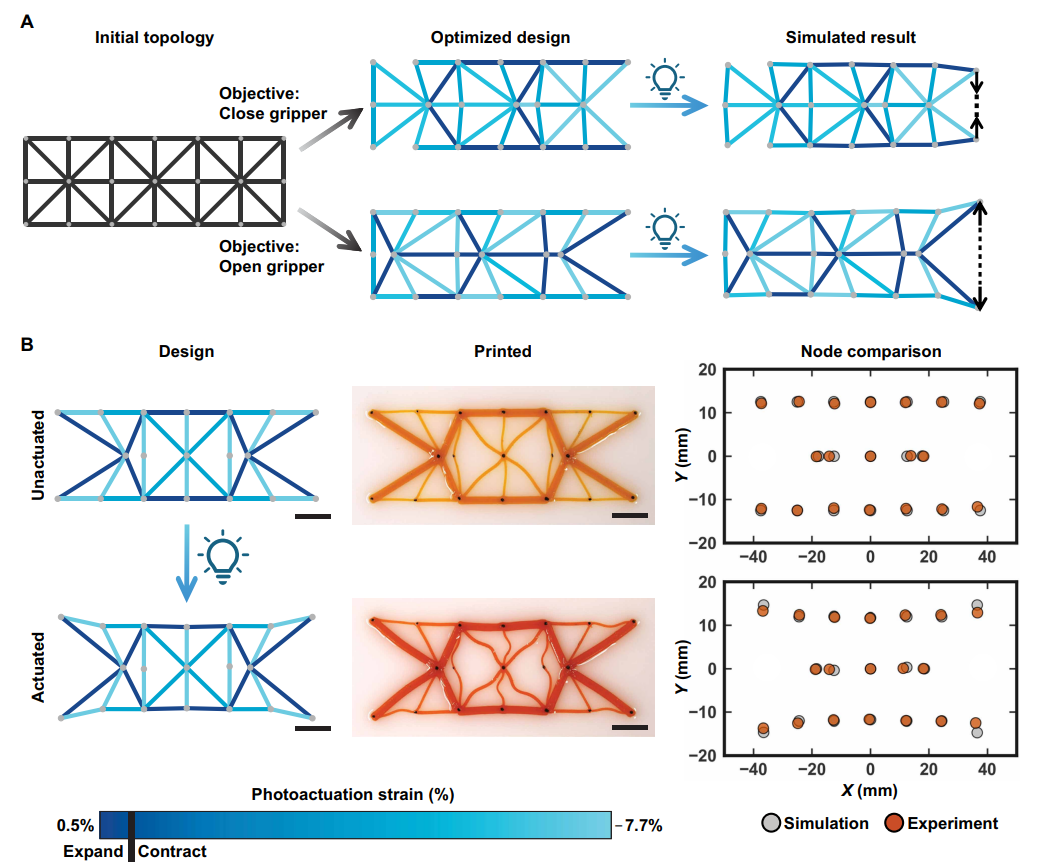

Photoresponsive morphing.

AzoLCE actuates under UV via azobenzene trans–cis isomerization but generates lower contractile forces than at elevated thermal states. The authors therefore calibrate the photoresponse by directly measuring photomechanical stress and scaling the spring models accordingly.

With that, they design and print an “open-gripper” that bends outward at both ends under UV. Despite frictional losses at the substrate reducing net displacement, node positions closely match simulation (R² ≈ 0.9985), validating the photo-calibrated pipeline.

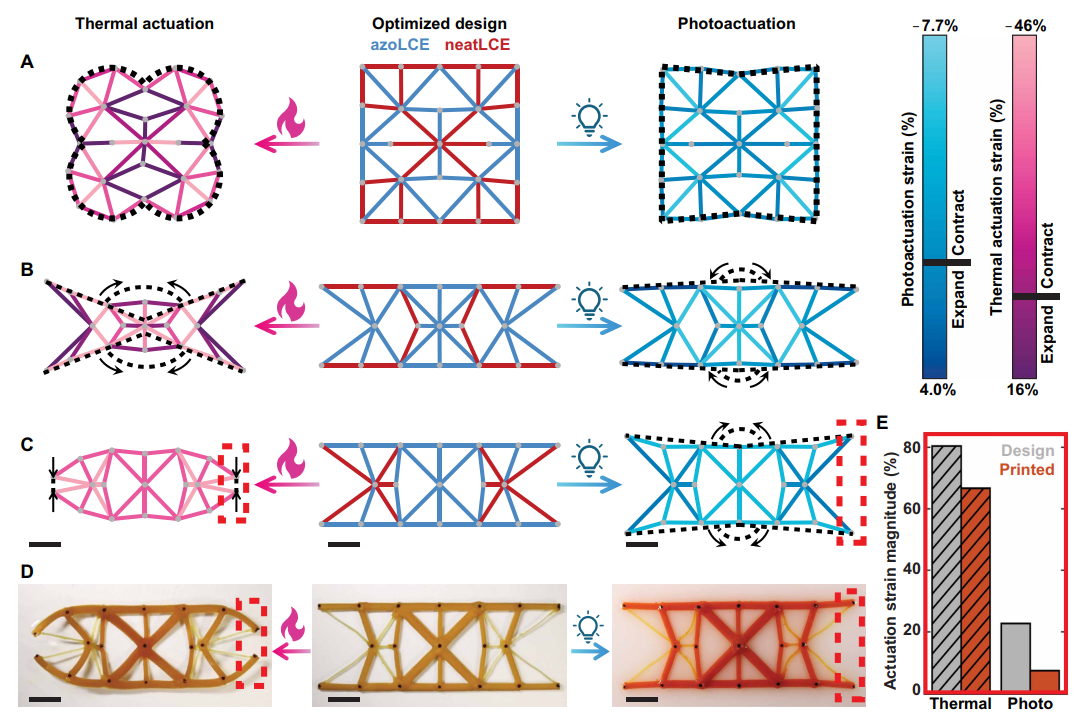

Multistimuli morphing.

Combining neatLCE (thermal only) and azoLCE (thermal + photo) at the edge level enables different shapes for heat and light in the same device. The framework aggregates objectives across stimuli and chooses which edges are azoLCE vs neatLCE while also tuning process parameters in each group.

Two instructive cases are presented: one design bends inward under UV but outward with heat; a second flips those outcomes. The optimizer resolves the conflict by switching which material group acts as the dominant actuator under each stimulus. Experiments confirm thermal actuation approaching predicted strain and qualitatively correct photoresponse, with reduced magnitude from friction and photothermal crosstalk in neatLCE.

Limitations and edge cases.

The spring-network model focuses on axial response and omits full bending and shear behavior, which can matter for local buckling. The authors mitigate out-of-plane buckling via thickness constraints and add linear buckling checks, but pronounced nonlinear buckling and residual stresses can still appear.

Extending to nonlinear beam or solid elements with high-fidelity, process-aware constitutive laws would improve coverage, albeit at significant modeling and data cost. Friction and photothermal side effects also emerge as practical factors during UV actuation.

Methods At A Glance

Materials: Two inks are used. A main-chain azobenzene-functionalized LCE (azoLCE) actuates under heat and UV, and a neat LCE (neatLCE) actuates thermally. Printing uses HOT-DIW with green-light photocrosslinking to preserve nematic alignment and avoid azobenzene activation during fabrication.

Process parameters: Edge-wise print speed, pressure, and number of passes are key knobs. Speed and pressure strongly modulate azoLCE actuation strain; generally, higher speed and lower pressure increase actuation, while passes set cross-section and stiffness.

Modeling: Measured stress–strain curves under room temperature, high temperature (above TNI), and post-UV exposure train neural surrogates. A differentiable spring-network simulation predicts equilibrium under prestrain. Gradients drive a generalized TO that maps mixed variables (continuous coordinates, discrete connections, categorical materials, and combinatorial process settings) into a continuous optimization with constraints on printability.

Interpretation Of Figures

Fig. 1. Autonomous codesign and fabrication framework. (A) Our framework designs multistimuli-responsive material systems from an initial design with target stimuli-specific morphing objectives. These inputs are fed into the (B) autonomous codesign framework, which models the behavior of responsive materials with a generalized NN-based spring model, capturing the effects of material/stimuli, topological, and manufacturing parameters (green, blue, and orange, respectively). A differentiable forward simulation evolves the spring network to generate actuated shapes and provides gradients for design variables. These gradients are used in a generalized TO method to iteratively update and codesign variables to match the objectives of interest. (C) Our framework provides edge-specific material placement, network topology, and manufacturing instructions (D) to yield an optimized morphing network design that achieves shape-morphing targets under multiple stimuli. Credit: Wang et al 2025.

Figure 1 (Framework schematic): Shows the codesign loop: target shapes for each stimulus feed a differentiable simulation; gradients update topology, geometry, material assignment, and process parameters; outputs are print instructions for each edge. The workflow is generic to different stimulus physics because the constitutive map is learned from data.

Fig. 2. Material actuation and influence of manufacturing parameters. (A) Left: Thermo- and phototropic LCEs contract under thermal and UV light stimuli, respectively. Gray ovals represent the liquid crystal mesogens, and orange ovals are the photoresponsive azobenzene photoswitch. Right: LCE elements are modeled as nonlinear springs. Their actuation force is predicted by NNs trained on LCE stress-strain characterization data. (B) Plots of print speed (in millimeters per second) versus actuation strain (%) for the azoLCE are provided for thermal and UV actuation. Color indicates print pressure. Error bars indicate SD over at least three actuation cycles for triplicates of each print parameter combination. (C) An example material system that can be produced by the framework. The framework uses iterative optimization to provide print speeds (left) and pressures (right) based on the stress-strain and actuation data. Edge thickness corresponds to the relative thickness of printed parts. Credit: Wang et al 2025.

Figure 2 (Material/process behavior): Left panels illustrate thermo- and photo-induced contraction mechanisms in LCEs. Middle/right panels quantify how print speed and pressure tune actuation strain, especially for azoLCE. These plots justify treating print settings as design variables rather than post hoc constraints.

Fig. 3. Designing thermoresponsive systems. Examples of material systems designed with (A) altered initial network topology or nodal density (shown in the gray insets) that achieve the same actuated circular shape under thermal actuation, (B) the same initial network topology that achieves different actuated morphing objectives, and (C) the ability to perform shape morphing where target and initial shapes are interchanged. The dashed outline represents the target actuated geometry, while the edge colors indicate the induced strain upon actuation, with lighter colors representing higher strain levels. Credit: Wang et al 2025.

Figure 3 (Thermal morphing designs): Demonstrates adaptability to initial topology, nodal density, and target shapes. The emergence of “skeleton” and “actuator” edge groups is visible via induced-strain color maps and cross-section allocations.

Fig. 4. 3D-printed thermoresponsive shape-morphing systems. Computational design, 3D prints, and experimental validation of thermoresponsive materials that undergo (A) square-to-circle, (B) shearing, and (C) circle-to-ellipse shape changes. In each, the top and bottom rows show data for unactuated and actuated states, respectively. For the nodal comparison data, each point corresponds to the nodal location of the experimental (orange) or computational (gray) data. Black dots on the printed structures indicate the nodal locations tracked for comparison. (D) A control experiment of (C) wherein the manufacturing parameters are ignored and set to fixed values. Scale bars, 10 mm (all). Credit: Wang et al 2025.

Figure 4 (Printed thermal morphing): Side-by-side comparison of simulated vs printed networks for square-to-circle, shearing, and circle-to-ellipse. The control case that ignores manufacturing instructions shows clear performance loss, reinforcing the codesign claim.

Fig. 5. Designed and 3D-printed photoresponsive shape-morphing systems. (A) Inputted initial network topology, optimized design, and simulated actuation performance of photoresponsive systems with opposite final objectives. Colors represent the edgewise level of photo-induced strain, with lighter colors indicating greater strain. (B) Design, 3D prints, and experimental validation of a two-mouthed open gripper. The top and bottom rows show data for unactuated and actuated states, respectively. For the nodal comparison data, each point corresponds to the nodal location of the experimental (orange) or computational (gray) data. Black dots on the printed structures indicate the nodal locations tracked for comparison. Scale bars, 10 mm (all). Credit: Wang et al 2025.

Figure 5 (Photo morphing): Optimized photo-only designs (open vs close grippers) and a printed open gripper validate the photo-calibrated models, while highlighting friction as a limiting factor for net motion.

Fig. 6. Designed and 3D-printed multistimuli-responsive shape-morphing systems. Optimized designs of multistimuli-responsive shape morphing systems with different photo- and thermo-specific objectives. Examples include a (A) shape-morphing square design, (B) photo-closing and thermal-opening gripper, and (C) photoopening and thermal-closing gripper with (D) experimental validation. Black dots on the printed structures indicate the nodal locations tracked for comparison. Red boxes indicate the region from which (E) the magnitude of the thermal and photoactuation strain is compared between the designed and experimental designs. For all, the center column shows the distribution of the azoLCE and neatLCE (blue and red, respectively). The left column shows the design under thermal actuation, and the right column shows the design under photoactuation. The level of actuated strain is indicated by color, with blue representing the photoresponsive strain and pink representing the thermoresponsive strain. Scale bars, 10 mm. Credit: Wang et al 2025.

Figure 6 (Multistimuli morphing): Different targets for heat and light in the same network. The optimizer assigns azoLCE vs neatLCE strategically and tunes speed/pressure/passes to ensure one stimulus dominates when objectives conflict.

Implications And Outlook

As an end-to-end, manufacturing-aware pipeline, this work moves programmable materials closer to "design-to-print-to-function." In practice, that means faster iteration, fewer failed prints, and architectures that exploit process heterogeneity intentionally. The paradigm should translate to other responsive material classes (magnetoactive elastomers, electroactive polymers, hydrogels), provided the constitutive surrogates are properly trained and the fabrication parameters are measurable and controllable.

Two developments could further broaden impact: (1) higher-fidelity, process-aware beam/solid models to capture bending/shear and nonlinear buckling robustly; and (2) multiobjective optimization front-ends to let engineers explicitly trade off performance across stimuli and tasks. Both are feasible given the differentiable foundation and growing ecosystem of physics-aware ML.

Conclusion

Wang and colleagues deliver a compelling demonstration of autonomous codesign for shape-morphing materials: a differentiable, data-grounded simulator embedded in a generalized TO framework, coupled to a multimaterial printing platform and validated across thermal, photo, and multistimuli regimes (Wang et al., 2025). The approach should inform how we engineer responsive systems going forward—by treating materials, structure, stimuli, and manufacturing as a single, optimizable whole.

Definitions

Liquid Crystal Elastomers (LCEs): Polymer networks with liquid-crystalline mesogens that can undergo large, reversible strains when mesogen order changes (thermally or optically).

Topology Optimization (TO): A computational design method that distributes material and architecture to optimize a performance objective under constraints (Sigmund & Maute, 2013).

Differentiable Simulation: A simulation in which outputs are differentiable with respect to inputs/parameters, enabling gradient-based optimization (Hu et al., 2019).

HOT-DIW: High-operating-temperature direct ink writing, a form of extrusion-based 3D printing that supports viscous inks and in situ curing (Kotikian et al., 2018).

Actuation Strain: The deformation (often contraction) induced in an element when stimulated (e.g., by heat or UV).

References

(Primary) Wang, L., Evenchik, A. L., Yang, J. M., Truby, R. L., & Chen, W. (2025). Autonomous codesign and fabrication of multistimuli-responsive material systems. Science Advances.

(Background) Sigmund, O., & Maute, K. (2013). Topology optimization approaches: A comparative review. Structural and Multidisciplinary Optimization.

(Background) Hu, Y., Anderson, L., Li, T.-M., Sun, Q., Carr, N., Ragan-Kelley, J., & Durand, F. (2019). Differentiable programming for physical simulation.

(Background) Kotikian, A., Truby, R. L., Boley, J. W., White, T. J., & Lewis, J. A. (2018). 3D printing of liquid crystal elastomeric actuators with spatially programmed nematic order. Advanced Materials.

AI Codesign For Multistimuli Shape-Morphing Materials

Autonomous codesign and fabrication of multistimuli-responsive material systems